Kingflex Foam Rubber Insulation Sheet Roll

Description

Kingflex foam rubber Insulation Sheet Roll is NBR/PVC-based closed cell, flexible elastomeric foam insulation. Kingflex foam rubber Insulation Sheet Roll is environmentally-friendly as it is free of CFCs, HFCs, HCFCs, PBDEs, formaldehyde and fibers.

Standard Dimension

|

Kingflex Dimension |

|||||||

|

Thickness |

Width 1m |

Width 1.2m |

Width 1.5m |

||||

|

Inches |

mm |

Size(L*W) |

㎡/Roll |

Size(L*W) |

㎡/Roll |

Size(L*W) |

㎡/Roll |

|

1/4" |

6 |

30 × 1 |

30 |

30 × 1.2 |

36 |

30 × 1.5 |

45 |

|

3/8" |

10 |

20 × 1 |

20 |

20 × 1.2 |

24 |

20 × 1.5 |

30 |

|

1/2" |

13 |

15 × 1 |

15 |

15 × 1.2 |

18 |

15 × 1.5 |

22.5 |

|

3/4" |

19 |

10 × 1 |

10 |

10 × 1.2 |

12 |

10 × 1.5 |

15 |

|

1" |

25 |

8 × 1 |

8 |

8 × 1.2 |

9.6 |

8 × 1.5 |

12 |

|

1 1/4" |

32 |

6 × 1 |

6 |

6 × 1.2 |

7.2 |

6 × 1.5 |

9 |

|

1 1/2" |

40 |

5 × 1 |

5 |

5 × 1.2 |

6 |

5 × 1.5 |

7.5 |

|

2" |

50 |

4 × 1 |

4 |

4 × 1.2 |

4.8 |

4 × 1.5 |

6 |

Technical Data Sheet

|

Kingflex Technical Data |

|||

|

Property |

Unit |

Value |

Test Method |

|

Temperature range |

°C |

(-50 - 110) |

GB/T 17794-1999 |

|

Density range |

Kg/m3 |

45-65Kg/m3 |

ASTM D1667 |

|

Water vapor permeability |

Kg/(m.s.pa) |

≤0.91×10 ﹣¹³ |

DIN 52 615 BS 4370 Part 2 1973 |

|

μ |

- |

≥10000 |

|

|

Thermal Conductivity |

W/(m.k) |

≤0.030 (-20°C) |

ASTM C 518 |

|

≤0.032 (0°C) |

|||

|

≤0.036 (40°C) |

|||

|

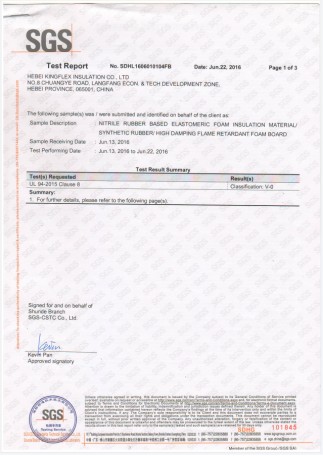

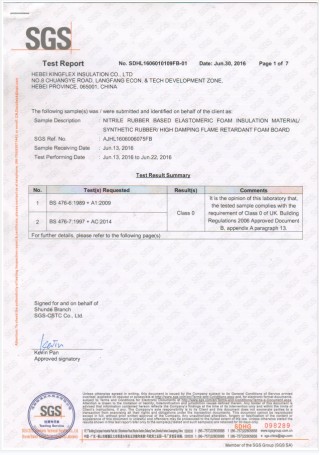

Fire Rating |

- |

Class 0 & Class 1 |

BS 476 Part 6 part 7 |

|

Flame Spread and Smoke Developed Index |

|

25/50 |

ASTM E 84 |

|

Oxygen Index |

|

≥36 |

GB/T 2406,ISO4589 |

|

Water Absorption,%by Volume |

% |

20% |

ASTM C 209 |

|

Dimension Stability |

|

≤5 |

ASTM C534 |

|

Fungi resistance |

- |

Good |

ASTM 21 |

|

Ozone resistance |

Good |

GB/T 7762-1987 |

|

|

Resistance to U.V. and weather |

Good |

ASTM G23 |

|

Packing

Packed in PE bags; We also can make OEM packing.

Advantages

hey are cost-effective, easy to install and highly flexible.

Elastomeric, Flexible, Soft Texture

Low thermal conductivity

Independent closed foam structure, good heat insulation performance.

Fire-resistant material

The rubber foam pipe lagging is resistant to water vapour.

They offer excellent adhesion to adhesives and coatings.

The insulation is easy to cut, carry and install. Installing nitrile rubber lagging on pipes is an easy DIY task.

It significantly reduces energy costs.

Our Company

Company exhibition

Certificate