2021 High quality Halogen-Free Insulation Material - KINGFLEX INSULATION FOR CRYOGENIC AND LOW TEMPERATURE APPLICATIONS DOWN TO -200 °C – Kingflex

2021 High quality Halogen-Free Insulation Material - KINGFLEX INSULATION FOR CRYOGENIC AND LOW TEMPERATURE APPLICATIONS DOWN TO -200 °C – Kingflex Detail:

Main advantage

Brief Description

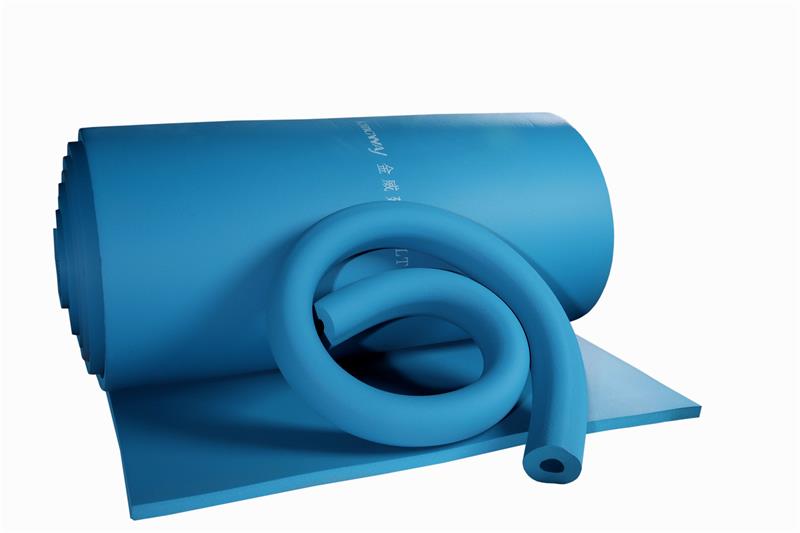

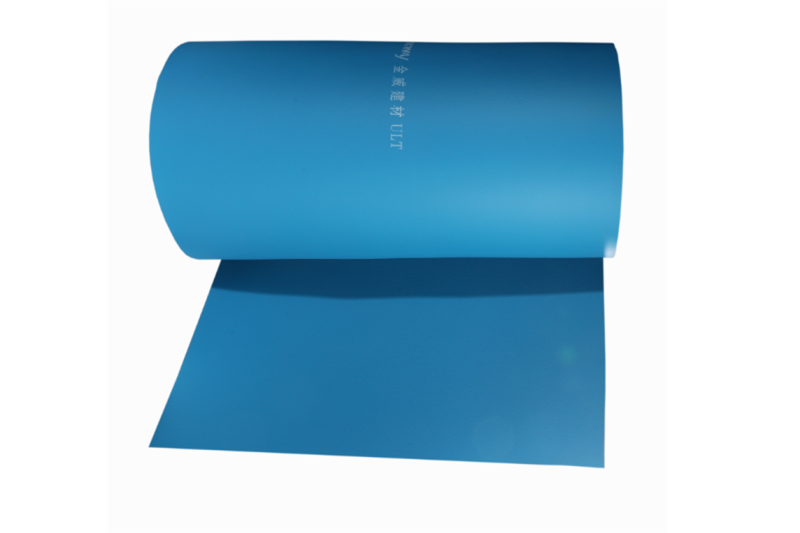

Kingflex ULT is a flexible, high density and mechanically robust, closed cell cryogenic thermal insulation material based on extruded elastomeric foam. The product has been specially developed for use on the import/export pipelines and process areas of liquefied natural gas (LNG) facilities. It is part of Kingflex Cryogenic multi-layer configuration, providing low temperature flexibility to the system.

•Stays flexible at low temperatures

• Reduces the risk of crack development and propagation

• Reduces the risk of corrosion under insulation

• Protects against mechanical impact and shock

• Low thermal conductivity

• Low glass transition temperature

• Easy installation even to complex shapes

• Less wastage compared to rigid / pre-fabricated pieces

Applications

Cryogenic thermal insulation / protection of pipes, vessels and equipment (incl. elbows, fittings, flanges etc.) in production plants for petrochemicals, industrial gases, LNG, agricultural chemicals and other process equipment facilities.

About Kingflex Insulation Company and Our Markets

In 1989, Kingway group was established(originally from Hebei Kingway New Bulding Materials Co., Ltd). In 2004, Hebei Kingflex Insulation Co., Ltd was established.

Over four decades, Kingflex Insulation Company has grown from a single manufacturing plant in China to a global organization with product installation in over 50 countries. From the National Stadium in Beijing, to the high rises in New York, Singapore and Dubai, people around the world are enjoying the quality products from Kingflex.

About Kingf;ex QC system

Kingflex have a professional, sound and strict Quality Control System. The product of every order will be checked from the raw material to the final product.

To keep stable quality, we Kingflex make out our own testing standard, which is a higher requirement than testing standard in domestic or abroad.

Product detail pictures:

Related Product Guide:

To create more benefit for buyers is our business philosophy; shopper growing is our working chase for 2021 High quality Halogen-Free Insulation Material - KINGFLEX INSULATION FOR CRYOGENIC AND LOW TEMPERATURE APPLICATIONS DOWN TO -200 °C – Kingflex , The product will supply to all over the world, such as: Houston, Belgium, Swaziland, We only supply quality products and we believe this is the only way to keep business continue. We can supply custom service too such as Logo, custom size, or custom products etc that can according to customer's requirement.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly

Product categories

-

Phone

-

E-mail

-

Whatsapp