Quality Inspection for Boat Insulation - elastomeric NBR/PVC rubber foam thermal insulation pipe tubing – Kingflex

Quality Inspection for Boat Insulation - elastomeric NBR/PVC rubber foam thermal insulation pipe tubing – Kingflex Detail:

Black, red, green and yellow color are all available.

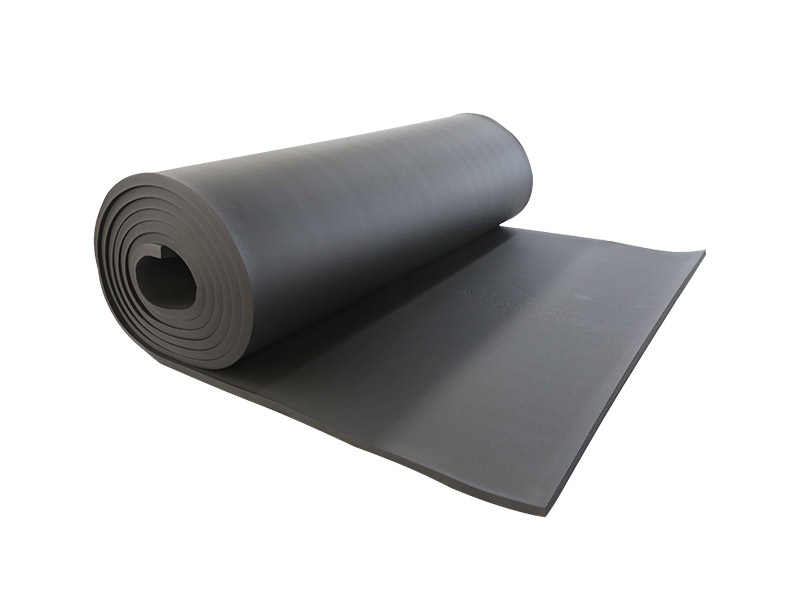

The expanded closed-cell structure of Kingflex Rubber Foam Insulation Tube makes it an efficient insulation. It is manufactured without the use of CFC’s, HFC’s or HCFC’s. It is also formaldehyde free, low VOCs, fiber free, dust free and resists mold and mildew. Kingflex Rubber Foam Insulation Tube can be made with special antimicrobial product protection for added defense against mold on the insulation.

|

Technical Data |

|||

|

Property |

Unit |

Value |

Test Method |

|

Temperature range |

°C |

(-50 – 110) |

GB/T 17794-1999 |

|

Density range |

Kg/m3 |

45-65Kg/m3 |

ASTM D1667 |

|

Water vapor permeability |

Kg/(m.s.pa) |

≤0.91×10 ﹣¹³ |

DIN 52 615 BS 4370 Part 2 1973 |

|

μ |

- |

≥10000 |

|

|

Thermal Conductivity |

W/(m.k) |

≤0.030 (-20°C) |

ASTM C 518 |

|

≤0.032 (0°C) |

|||

|

≤0.036 (40°C) |

|||

|

Fire Rating |

- |

Class 0 & Class 1 |

BS 476 Part 6 part 7 |

|

Flame Spread and Smoke Developed Index |

25/50 |

ASTM E 84 |

|

|

Oxygen Index |

≥36 |

GB/T 2406,ISO4589 |

|

|

Water Absorption,%by Volume |

% |

20% |

ASTM C 209 |

|

Dimension Stability |

≤5 |

ASTM C534 |

|

|

Fungi resistance |

- |

Good |

ASTM 21 |

|

Ozone resistance |

Good |

GB/T 7762-1987 |

|

|

Resistance to U.V. and weather |

Good |

ASTM G23 |

|

Standard Dimensions

|

NO. |

Copper Tube |

Steel Pipe |

Internal Φ mm |

9mm ·3/8″FF |

13mm ·1/2″HH |

19mm ·3/4″MM |

25mm ·1″RR |

|||||||

|

Nom. ID Inches |

Nom. ID Inches |

I.PS. Inches |

Φ External mm |

Φ Nominal mm |

Ref. Wall*ID |

Lengths (2m) per cart |

Ref. Wall*ID |

Lengths (2m) per cart |

Ref. Wall*ID |

Lengths (2m) per cart |

Ref. Wall*ID |

Lengths (2m) per cart |

||

|

1 |

1/4 |

6.4 |

7.1 8.5 |

9*06 |

170 |

13*6 |

90 |

19*6 |

50 |

25*6 |

35 |

|||

|

2 |

3/8 |

9.5 |

1/8 |

10.2 |

6 |

11.1 12.5 |

9*09 |

135 |

13*10 |

80 |

19*10 |

40 |

25*10 |

25 |

|

3 |

1/2 |

12.7 |

12.5 |

13.1 14.5 |

9*13 |

115 |

13*13 |

65 |

19*13 |

40 |

25*13 |

25 |

||

|

4 |

5/8 |

15.9 |

1/4 |

13.5 |

8 |

16.1 17.5 |

9*16 |

90 |

13*16 |

60 |

19*16 |

35 |

25*16 |

20 |

|

5 |

3/4 |

19.1 |

19.0 20.5 |

9*19 |

76 |

13*19 |

45 |

19*19 |

30 |

25*20 |

20 |

|||

|

6 |

7/8 |

22.0 |

1/2 |

21.3 |

15 |

23.0 24.5 |

9*22 |

70 |

13*22 |

40 |

19*22 |

30 |

25*22 |

20 |

|

7 |

1 |

25.4 |

25.0 |

26.0 27.5 |

9*25 |

55 |

13*25 |

40 |

19*25 |

25 |

25*25 |

20 |

||

|

8 |

1 1/8 |

28.6 |

3/4 |

26.9 |

20 |

29.0 30.5 |

9*28 |

50 |

13*28 |

36 |

19*28 |

24 |

25*28 |

18 |

|

9 |

32.0 |

32.5 35.0 |

9*32 |

40 |

13*32 |

30 |

19*32 |

20 |

25*32 |

15 |

||||

|

10 |

1 3/8 |

34.9 |

1 |

33.7 |

25 |

36.0 38.0 |

9*35 |

36 |

13*35 |

30 |

19*35 |

20 |

25*35 |

15 |

|

11 |

1 1/2 |

38.0 |

38.0 |

39.0 41.0 |

9*38 |

36 |

13*38 |

24 |

19*38 |

17 |

25*38 |

12 |

||

|

12 |

1 5/8 |

41.3 |

1 1/2 |

42.4 |

32 |

43.5 45.5 |

9*42 |

30 |

13*42 |

25 |

19*42 |

17 |

25*42 |

12 |

|

13 |

44.5 |

44.5 |

45.5 47.5 |

9*45 |

25 |

13*45 |

20 |

19*45 |

16 |

25*45 |

12 |

|||

|

14 |

1 7/8 |

48.0 |

1 1/2 |

48.3 |

40 |

49.5 51.5 |

9*48 |

25 |

13*48 |

20 |

19*48 |

15 |

25*48 |

12 |

|

15 |

2 1/8 |

54.0 |

54.0 |

55.0 57.0 |

9*54 |

25 |

13*54 |

20 |

19*54 |

15 |

25*54 |

10 |

||

|

16 |

2 |

57.1 |

57.0 |

58.0 60.0 |

13*57 |

18 |

19*57 |

12 |

25*57 |

9 |

||||

|

17 |

2 3/8 |

60.3 |

2 |

60.3 |

50 |

61.5 63.5 |

13*60 |

18 |

19*60 |

12 |

25*60 |

9 |

||

|

18 |

2 5/8 |

67.0 |

67.5 70.5 |

13*67 |

15 |

19*67 |

10 |

25*67 |

8 |

|||||

|

19 |

3 |

76.2 |

2 1/2 |

76.1 |

65 |

77.0 79.5 |

13*76 |

12 |

19*76 |

10 |

25*76 |

6 |

||

|

20 |

3 1/8 |

80.0 |

13*80 |

12 |

19*80 |

10 |

25*80 |

6 |

||||||

|

21 |

3 1/2 |

88.9 |

3 |

88.9 |

80 |

90.5 93.5 |

13*89 |

10 |

19*89 |

8 |

25*89 |

6 |

||

|

22 |

4 1/4 |

108.0 |

108.0 |

108 111 |

13*108 |

6 |

19*108 |

6 |

25*108 |

5 |

||||

|

Tolerance: Thickness |

士 1.3mm |

士 2.0mm |

士 2.4mm |

士 2.4mm |

||||||||||

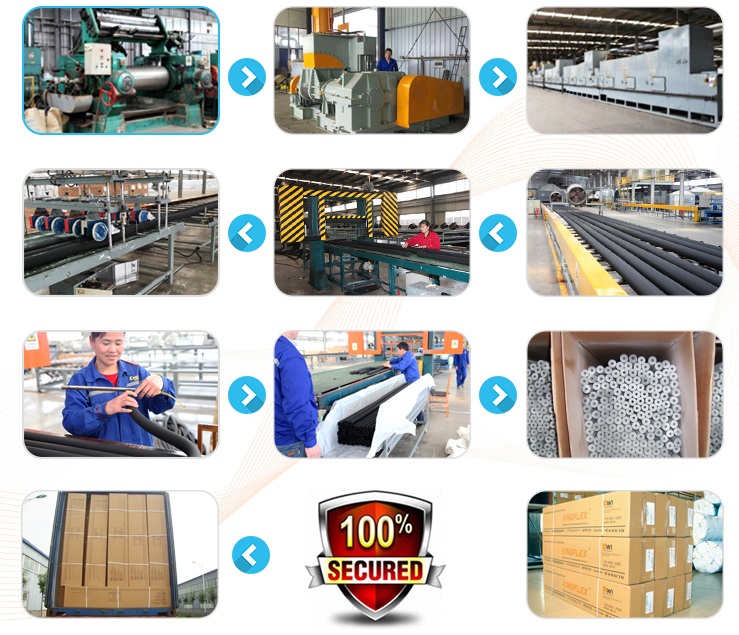

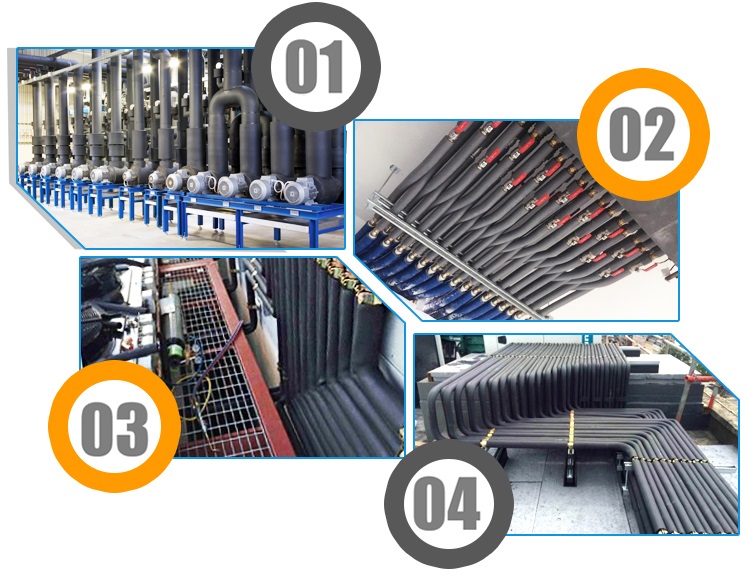

Production process

Application

Kingflex Rubber Foam Insulation Tube is used to retard heat gain and control condensation drip from chilled-water and refrigeration systems. It also efficiently reduces heat flow for hot-water plumbing and liquid-heating and dual-temperature piping. The recommended temperature usage range for Kingflex Rubber Foam Insulation Tube is -297°F to +220°F(-183°C to +105°C).

For use on cold pipes, Kingflex Rubber Foam Insulation Tube thicknesses have been calculated to control condensation on the insulation outer surface, as shown in the table of thickness recommendations.

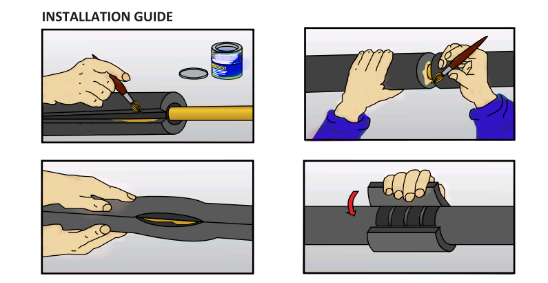

Installation

Product detail pictures:

Related Product Guide:

Innovation, quality and reliability are the core values of our company. These principles today more than ever form the basis of our success as an internationally active mid-size company for Quality Inspection for Boat Insulation - elastomeric NBR/PVC rubber foam thermal insulation pipe tubing – Kingflex , The product will supply to all over the world, such as: Mongolia, Birmingham, Angola, We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!

Product categories

-

Phone

-

E-mail

-

Whatsapp