Factory making Rubber Foam Insulation Tape - elastomeric NBR/PVC rubber foam thermal insulation tape – Kingflex

Factory making Rubber Foam Insulation Tape - elastomeric NBR/PVC rubber foam thermal insulation tape – Kingflex Detail:

Uses

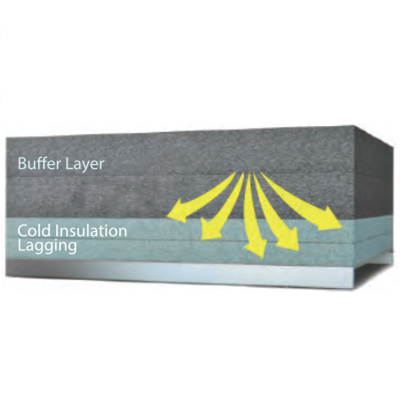

KingWrap provides a fast, easy method of insulating pipes and fittings. It is used to control condensation drip on domestic cold-water, chilled-water, and other cold piping bond with metal surfaces. On cold piping and fittings and to reduce heat loss when applied to hot-water lines that will operate up to 180°F(82°C). KingWrap may be used in conjunction with Kingflex Pipe and Sheet Insulation. Its greatest advantage, however, is the ease with which it can be used to insulate short lengths of pipe and fittings in congested or hard-to-reach areas.

Application Instructions

KingWrap is applied by removing release paper as the tape is spirally bond with metal surfaces. On cold piping, the number of wraps required must be sufficient to keep the outer insulation surface above the dew point of the air so that sweating will be controlled. On hot lines, the number of wraps is dictated only by the amount of heat loss control that is desired. On dual-temperature lines, any number of wraps sufficient to control sweating on the cold cycle is usually adequate for the heating cycle.

Multiple wraps are recommended. Tape should be applied with a spiral wrap to obtain a 50% overlap. Additional layers are added to build up insulation to the required thickness.

To insulate valves, tees, and other fittings, small pieces of tape should be cut to size and pressed into place, with no metal exposed. The fitting then is additionally over-wrapped with longer lengths for a durable and efficient job.

Kingflex provides this information as a technical service. To the extent the information is derived from sources other than Kingflex, Kingflex is substantially, if not wholly, relying upon the other source(s) to provide accurate information. Information provided as a result of Kingflex’s own technical analysis and testing is accurate to the extent of our knowledge and ability, as of date of printing, using effective standardized methods and procedures. Each user of these products, or information, should perform their own tests to determine the safety, fit-ness and suitability of the products, or combination of products, for any foresee-able purposes, applications and uses by the user and by any third party to which the user may convey the products. Since Kingflex cannot control the end use of this product, Kingflex does not guarantee that the user will obtain the same results as published in this document. The data and information are provided as a technical service and are subject to change without notice.

Product detail pictures:

Related Product Guide:

Trustworthy good quality and excellent credit score standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of "quality first, buyer supreme" for Factory making Rubber Foam Insulation Tape - elastomeric NBR/PVC rubber foam thermal insulation tape – Kingflex , The product will supply to all over the world, such as: Durban, Armenia, Qatar, Our Company policy is "quality first, to be better and stronger, sustainable development" . Our pursuit goals is "for society, customers, employees, partners and enterprises to seek reasonable benefit". We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.