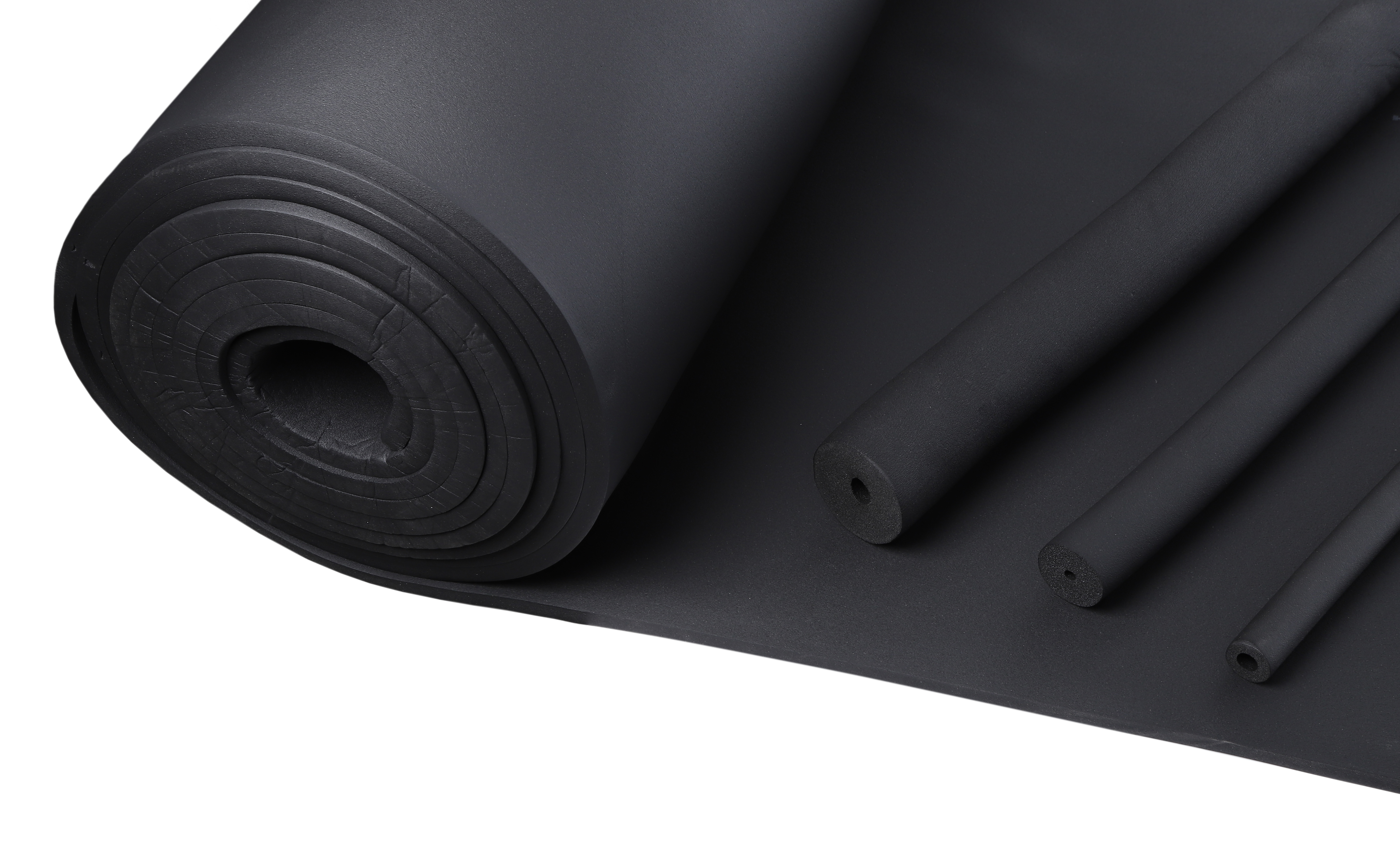

100% Original Fire Wall Penetration Sleeve - Closed Cell NBR Rubber Foam Insulation – Kingflex

100% Original Fire Wall Penetration Sleeve - Closed Cell NBR Rubber Foam Insulation – Kingflex Detail:

Product Description

The Fire rating standard method of tests conducted under controlled laboratory conditions is a measure of a material to spread flame when compared to a known standard and is not intended to reflect hazards presented by this or any material under actual fire conditions.

Standard Dimension

|

Kingflex Dimension |

|||||||

|

Thickness |

Width 1m |

Width 1.2m |

Width 1.5m |

||||

|

Inches |

mm |

Size(L*W) |

㎡/Roll |

Size(L*W) |

㎡/Roll |

Size(L*W) |

㎡/Roll |

|

1/4″ |

6 |

30 × 1 |

30 |

30 × 1.2 |

36 |

30 × 1.5 |

45 |

|

3/8″ |

10 |

20 × 1 |

20 |

20 × 1.2 |

24 |

20 × 1.5 |

30 |

|

1/2″ |

13 |

15 × 1 |

15 |

15 × 1.2 |

18 |

15 × 1.5 |

22.5 |

|

3/4″ |

19 |

10 × 1 |

10 |

10 × 1.2 |

12 |

10 × 1.5 |

15 |

|

1″ |

25 |

8 × 1 |

8 |

8 × 1.2 |

9.6 |

8 × 1.5 |

12 |

|

1 1/4″ |

32 |

6 × 1 |

6 |

6 × 1.2 |

7.2 |

6 × 1.5 |

9 |

|

1 1/2″ |

40 |

5 × 1 |

5 |

5 × 1.2 |

6 |

5 × 1.5 |

7.5 |

|

2″ |

50 |

4 × 1 |

4 |

4 × 1.2 |

4.8 |

4 × 1.5 |

6 |

Technical Data Sheet

|

Kingflex Technical Data |

|||

|

Property |

Unit |

Value |

Test Method |

|

Temperature range |

°C |

(-50 – 110) |

GB/T 17794-1999 |

|

Density range |

Kg/m3 |

45-65Kg/m3 |

ASTM D1667 |

|

Water vapor permeability |

Kg/(m.s.pa) |

≤0.91×10 ﹣¹³ |

DIN 52 615 BS 4370 Part 2 1973 |

|

μ |

- |

≥10000 |

|

|

Thermal Conductivity |

W/(m.k) |

≤0.030 (-20°C) |

ASTM C 518 |

|

≤0.032 (0°C) |

|||

|

≤0.036 (40°C) |

|||

|

Fire Rating |

- |

Class 0 & Class 1 |

BS 476 Part 6 part 7 |

|

Flame Spread and Smoke Developed Index |

25/50 |

ASTM E 84 |

|

|

Oxygen Index |

≥36 |

GB/T 2406,ISO4589 |

|

|

Water Absorption,%by Volume |

% |

20% |

ASTM C 209 |

|

Dimension Stability |

≤5 |

ASTM C534 |

|

|

Fungi resistance |

- |

Good |

ASTM 21 |

|

Ozone resistance |

Good |

GB/T 7762-1987 |

|

|

Resistance to U.V. and weather |

Good |

ASTM G23 |

|

Product Advantage

♦ Good flexibility at low temperature

♦ Clean,dust-free,fast and easy installation

♦ Low thermal conductivity

♦ Good uniform products quality appearances

♦ High water vapor resistance factor,>5500

Our Company

Company Exhibition

Company Certificate

Product detail pictures:

Related Product Guide:

With the "Client-Oriented" business philosophy, a rigorous quality control system, advanced manufacturing equipment and a strong R&D team, we always provide high quality products, excellent services and competitive prices for 100% Original Fire Wall Penetration Sleeve - Closed Cell NBR Rubber Foam Insulation – Kingflex , The product will supply to all over the world, such as: Islamabad, Haiti, Brunei, The credibility is the priority, and the service is the vitality. We promise we have the ability to provide excellent quality and reasonable price products for customers. With us, your safety is guaranteed.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!

Product categories

-

Phone

-

E-mail

-

Whatsapp